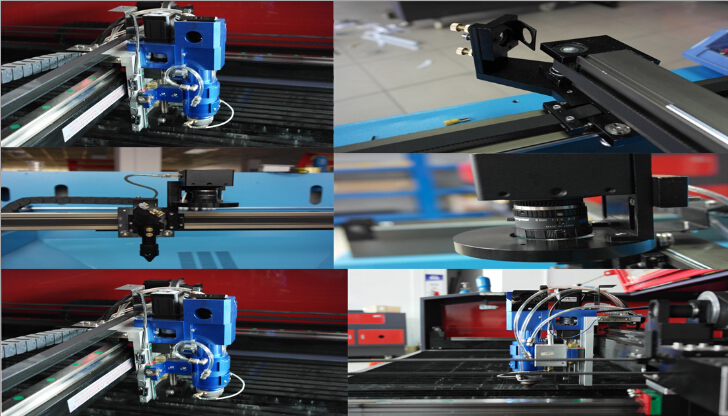

Equipment introduction

Laser cutting machine is a special machine for the production of high precision products and high accuracy, which is mainly reflected in two major characteristics of high speed and high accuracy. Machine uses the X axis and Y axis subdivision step into the system, imported three-phase stepper motor, not rusty iron honeycomb floor or knife, aluminium slats platform, Singapore optical path system, in circuit control system using DSP control technology, high efficiency and stability of the switching power supply, USB data transmission, the machine more stable, faster, higher precision, which is widely used in carving handicraft, rubber printing plate engraving, electronic products carving, photography image engraving, model engraving of carving precision requirements relatively high industry.

Equipment characteristics

Laser cutting machine is faster and more efficient, but the ability of this machine is not only can cut metal, but also can not be cut metal, use the same configuration can be cut with different material thickness. In addition, metal non metal hybrid laser cutting machine and laser cutting machine, the advantages of clear, high precision, high precision, high accuracy and high precision. Fully automatic constant focus cutting, effectively guarantee the cutting quality.

1 metal and nonmetal hybrid laser cutting machine with high performance ratio and high performance price ratio.

2. Reliable quality of the products comprehensive processing capacity (mixed cutting, processing of stainless steel, carbon steel, acrylic, density board, knife mold)

3 low investment cost, low operating cost, low maintenance cost.

4 metal non contact with the configuration, so that you spend a little money to cover the maximum range of material processing.

5 knife table type laser cutting bed using the full open type knife work platform, the special treatment, easy to operate, never wear, for all kinds of hard materials processing.

6 using a solid working class of machine tools to ensure the stability and accuracy of the fast motion.

7 motion system using linear guide and precision gear, with advanced DSP control of the high accuracy of three stepper motor drives, to ensure the accuracy of processing.

8 beam more stable new high-speed laser tube, the use of life for more than 10000 hours.

9 the Bodor series laser cutting bed for the industrial site can be selected and the whole automatic transmission system can be used to save time, save cost and improve working efficiency.

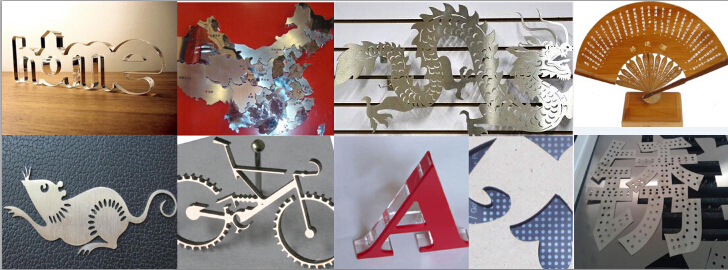

Application domain

Widely used in advertising signs, metal structure, high and low voltage electrical cabinet production, textile machinery, kitchen utensils and appliances, automobiles, machinery, electric saws, precision parts, parts of the subway, metal crafts and so on

Applicable materials

Stainless steel, carbon steel, copper, alloy steel, aluminum, steel, spring steel, galvanized sheet, plating aluminum, titanium alloy, etc.

Technical parameters

Product model types of ZY-960T ZY-1080T ZY-1280T ZY-1390T ZY-1490T ZY-1610T ZY-1810T (processing format according to custom)

Laser type CO2 laser

Laser power 150W/200W/300W

1400*900mm 1600*1000mm 1800*1000mm 2500*1300mm 3000*1500mm 1300*900mm

Cutting speed 0-200mm/s

Repeat accuracy 0.03mm

Motion system CNC control system

Cooling mode forced water cooling and protection system

Working voltage: 220 + 10% 50HZ

Machine power 2200W

Working temperature 0 -45

Working humidity 5%-95%

ontrol software genuine laser software

PLT AI DXF DST BMP

Dimension 1850*1450*1050

Machine weight 20kg/270kg/290kg/310kg/500kg/650kg

Main configuration

1 original imported stepper motor and drive system

2 domestic laser (60/80/100/150/200W) matching

3 use of foreign imported linear guide

4 double transmission mode: Industrial serial port, USP serial port

5 subtitles LCD screen, the human nature of the key control panel

6 optical path system using the full import of Singapore laser lens system

7 high strength stainless steel plate or aluminum honeycomb board optional knife

8 CMLASER control system

9 PCI card /USB interface on line / off machine directly read U disk |

Constant Company Home

Constant Company Home ST Robotics Column

ST Robotics Column MRW Workholding System

MRW Workholding System