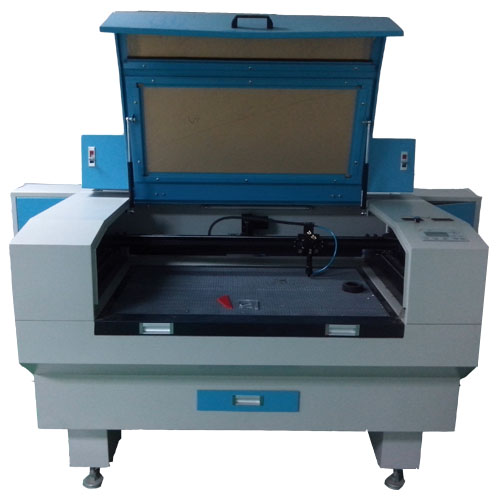

Principle of equipment:

Organic glass CO2 laser cutting machine CE-CO100Q is a high power density energy which is produced by laser focusing. In cutting, a unit of coaxial gas flow from the beam is emitted, and the material is blown out by the bottom of the cut. Compared with the traditional method of sheet metal processing, laser cutting has the advantages of high cutting quality, high cutting speed, high flexibility, wide material adaptability and so on.

Equipment characteristics:

1, support a variety of CAD professional graphics software, eliminating the trouble of graphics data conversion.

2, good quality, good appearance, appearance, beautiful, no need to deal with.

3, large memory capacity, can be used offline.

4, cutting is located in no pollution, heat should be small, simple operation, high cutting precision

Application industry:

Applicable to the wood carving, double color board, organic glass and stone, wood processing, printing and packaging, craft jewelry, advertisement decoration, architectural models, simulation model, leather clothing, electronics industry, die-cutting plate manufacturing and sheet metal processing industry.

Main technical parameters:

Model CE-CO100Q

The cutting area 900*600mm

Maximum workpiece size 1200* ~ *40mm

Cutting speed 1-400mm/sec

Repeat accuracy of less than 0.05mm

Control platform XP WIN work piece, can work offline

Work mode vector

Cutting platform bar or cell

Focus lens configuration standard 3"

Optical path structure flight path

Drive control synchronous belt / stepping motor

Ventilation equipment outlet is 8"

Machine tool net weight 220kg

Dimension 1700*1160*1050mm |

Constant Company Home

Constant Company Home ST Robotics Column

ST Robotics Column MRW Workholding System

MRW Workholding System